references

DFMA transport module die-bonding

Nexperia ITEC’s die-bonders have been around for ten years, but it was decided to review some of the modules. Using the DFMA method, the price of the transport module fell by almost a third.

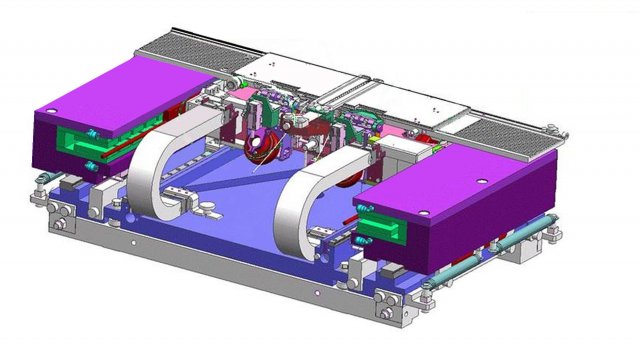

cryostat vibration isolation

For improved subatomic particle research, ACE has designed a construction that reduces the vibrations of the cryostat. A multidisciplinary team designed and realised a solution for vibration isolation with a double frame.

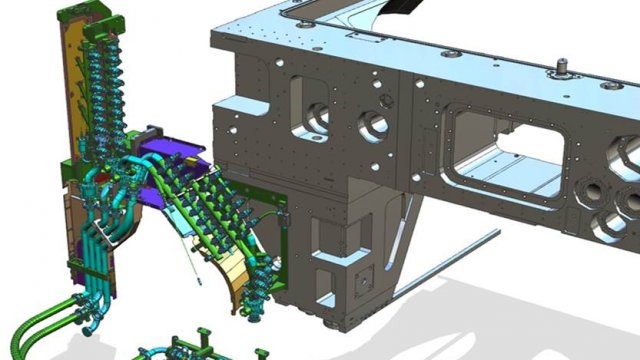

FLOW & TEMPERATURE SYSTEMS

To achieve nanometre positioning accuracy in semiconductor production machines, high temperature stability and contamination control is crucial.