InMotion is a team of ambitious students mainly from the TU / e (Eindhoven University of Technology) and Fontys Hogeschool. They want to compete in the 24 Hours of Le Mans with a hybrid powertrain through 'Garage 56'. To achieve that goal, a full electrical test platform (IMe) was first developed to test the components of the electrical powertrain on a circuit. In 2016 they want to break the lap record for electric cars with this car at Circuit Zandvoort and the Nürnburgring Nordschleife.

ACE has supported InMotion with the packaging of the powertrain components.

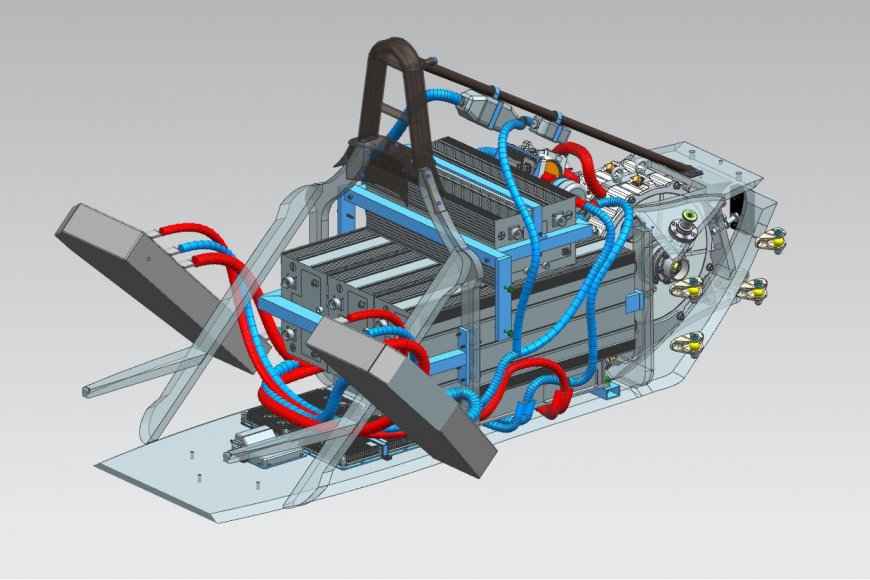

Part of the frame was already defined and the drivetrain components themselves were already known. The packaging must meet a number of aspects. For example, it must be possible to change the battery. In addition, the drivetrain components must be cleverly placed in relation to the center of gravity and the suspension geometry.

Given the weight of the drivetrain parts compared to the other parts, these have a strong influence on the handling, the understeer or oversteer behavior, the maximum cornering speed, the grip of the driven wheels and the effectiveness of the brakes. The mounting of the drivetrain parts in the frame also requires extra attention. Obviously, the mounting itself must also be light.

However, a car on a track also has to handle a considerable amount of G forces. Part of this is in “long-term” forces during cornering and acceleration and braking. A large part is in the vibrations and shocks. Full acceleration over the curb stones is a good example.

ACE has carried out the following activities: