career story Bea Driessen Lummen

FINDING SOLUTIONS FOR VARIOUS ISSUES

Bea Driessen (25) starts off by saying: "I am only a small part of a process". "As a Mechanical Draughtsman - Designer at ACE, I assist one of the main designers in finding solutions to various problems. How can I optimise a machine, improve it and make it more efficient?" Bea does not do this on her own. Together with colleagues they start from scratch. "If there is a problem on the table, then we all sit around brainstorming to find the right solution. Everyone has their own expertise to help create a machine that functions optimally."

FROM DRAWING TO ASSEMBLY FACILITY

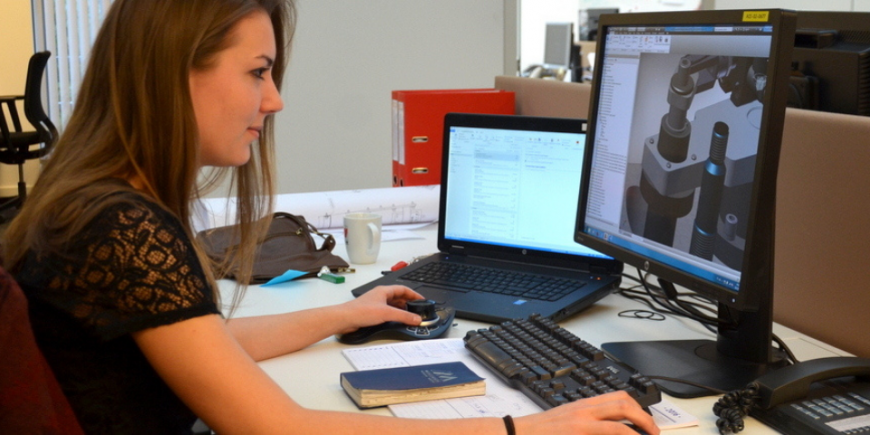

Bea then sits at her computer to design a certain component for a machine.

When making a drawing - at a very detailed level - you literally need to leave room in your design for other departments. "We need to remember that all the sensors must be drawn so that they are clearly visible. Sometimes we even need to draw them another way, so that the electrical department still has access." The fact that you form part of a larger process means that you have to consult with other colleagues and go back to the drawing table to produce a good final product together.

"I show my colleagues my first sketch, receive feedback and then go back to the drawing table. Sometimes, this process reveals that our idea will not work in practice. For example, the mechanical solution turns out not to be the best solution." Problems are revealed during this drawing table process. Another point at which to check here designs is the moment that the design is actually manufactured in the assembly hall. "This is the place where I can see whether my designs fit or whether adjustments need to be made."

project based work

The problems and products are different every time. "At ACE I get a lot of orders from different customers. Within ACE, we complete these assignments as a team, in which I focus on the drawing work. Orders that I have performed drawing work for include an ultrasonic welding machine, a production line for swimming pool covers and I have assisted in the optimisation order for a stickering machine for gear flanks." Bea finds the projects with nothing on the table the most challenging. "In those cases you are allowed to come up with something new. You get to decide the direction you want to go in from scratch. Sometimes you know what needs to happen, because there is a concept, but you have a lot of freedom within that concept to find a way to answer the question."

An example of a very challenging project is the machine that produces a sensor to measure the temperature of metal in a smelter. "The product already exists, but the assembly of the various components presents a challenge, because everything needs to be very accurate. This is fine mechanics. We re-develop an existing machine so that it operates more effectively" explains Bea.

one of the guys

Bea is not alone during the design process, she works in a team. An all-male team. "Personally, I don't feel that I am very different, even though I am the only young woman. The men are all very friendly and treat me with care. In general, there are very few differences. I am simply one of the guys." Bea thinks that the open atmosphere at ACE ensures that everything can be discussed and that it does not really matter whether you are male or female. She would like to see more women working in technological jobs. "It was never a big issue for me, my mother is also an engineer. She did always tell me that she found it harder because she is a woman. But I have not experienced this. At home I am also the one who fixes things when they are broken."

Her experience with technology started at an early age. "I was often doing something related to technology with my father. If something was broken, we would try to find out what the problem was. Thinking and finding solutions and just fiddling about a bit. That is basically what I am still doing at ACE." Of course Bea now has a lot more knowledge and works on a totally different level. And that level continues to grow as she gains more experience at ACE. "ACE offers me plenty of opportunities for growth and supports me in my development. Right now this is the best place for me."

LOOKING FOR A NEW CHALLENGE?

Check out our vacancies now and apply online today! Our team will be happy to help you discover your possibilities at ACE development & engineering.