Career story Klaas De Smedt Gent

After obtaining a Master's degree in Electro-Mechanical Engineering, Klaas started his career at ACE in Hasselt in his early twenties - this branch office moved to nearby Lummen in August 2013.

"I met my wife whilst I was still studying in Oostende, in the village where I grew up. She was studying in Leuven at the time, where she was given the opportunity to complete a PhD after her graduation. I moved to Leuven, to live with her. Newly graduated, I was looking for work and I was looking at companies that were not located in the direction of Brussels, purely because of the busy traffic around this city in the mornings. This is when I decided to work for ACE, which was located in Hasselt at the time."

From ACE Hasselt to ACE Lummen

One year before ACE Hasselt became ACE Lummen, Klaas moved too. From one side of the country to the other. Fortunately he did not need to switch to a new employer: ACE Ghent became his new place of work. He still returns to ACE Lummen regularly.

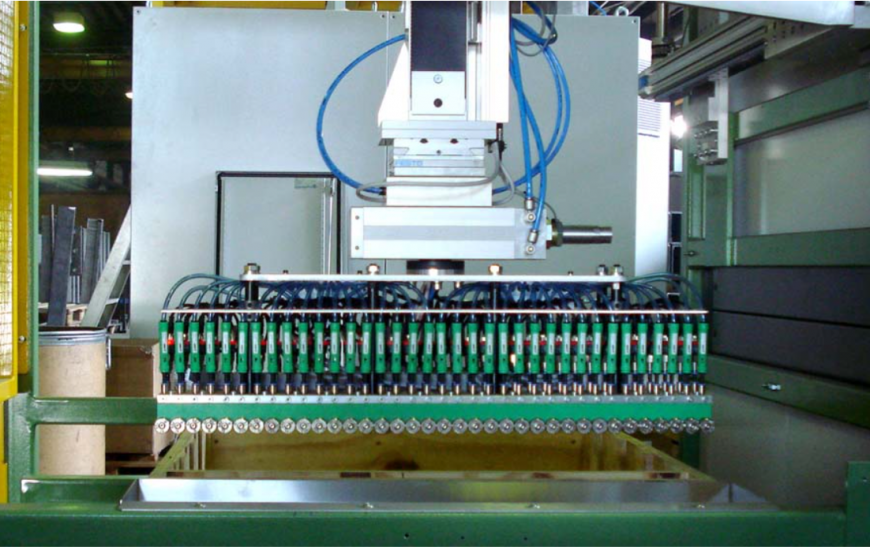

"I like being able to keep in touch with my old colleagues. Sometimes, when I am struggling with something or if it is necessary for a project, I will travel back and forth. For example because of the assembly hall in Lummen. When some assembly was required for one of my projects, I had this done in Lummen." I think it is unique that this is possible within an organisation such as ACE, it makes my work more versatile!

At the time that Klaas left Hasselt, there were still some ongoing projects for a major client, a customer relationship that he had helped to establish for ACE. He was able to complete these projects in Ghent. "This mainly involved completing a study of a machine that I was working on, the design aspects. There were many phone calls back and forth about the projects."

Plate thickness of 30 - 40 mm

Klaas started at ACE as a draughtsman/designer. His first project was for a supplier of a car assembly and parts factory. Initially he gained experience doing "mainly small drawing jobs", but as he developed further at ACE, he started going more in the direction of design.

"To me, the best part about designing is the variation. Both in the drawing work and in the problems that you need to solve. One customer asks you to perform drawing work for frames across roads to attach signalling boards to, another customer ask you to design a manipulator. This really covers the full range of materials and orders of magnitude."

One project that holds special memories for Klaas is the nuclear reactor in Doel. He performed the drawing work for the fitting of an emergency break on a retractable bridge weighing 130 tonnes.

"Instead of a band break, the customer wanted a drum break, because of the much shorter breaking distance. In that case you are talking about a plate thickness of 30 - 40 mm that is being used."

Inventor expert

A phrase that is used a lot at ACE is: "Be Ingenious". When asked what makes him ingenious, Klaas answered as follows:

"My colleague from Hasselt - Freddie Willems - once said that I was a "lazy engineer". In the sense that if I can automate a process to make it easier in the future then I will usually do that. You should not be trying to re-invent the wheel every time. Over the years I have become very good at automation and programming using Inventor, the drawing programme that we use here."

Klaas mainly has experience in PCS Software (Quality Management Software) and Inventor. He acts as a sort of helpdesk for his colleagues. "Every now and then I receive phone calls from Lummen or Limburg with technical questions "Klaas, how does this work?". Yes, they know how to find me then", he laughs.

As part of his training, Klaas also knows a fair bit about the mechanics of materials and strength calculations:

‘I also use Inventor regularly to perform strength calculations on more complex structures, even though it is primarily used as a design tool and less to serve as a certificate saying: "this is strong enough". When the customer does ask "is this strong enough?", we usually outsource this to a company that is - of course - specialised in this. But we definitely use the strength calculations to create a design that is not too heavy and has been thoroughly tested as far as the forces exerted on it are concerned."

"The strength is not that important for small designs, because the percentage weight is lower. But this can make a difference once you start using larger structures or create larger constructions. You usually have the feeling that something can never be strong enough, but then you find out that it is stronger than you initially thought."

Team building at ACE

At ACE we understand the need for healthy competition every now and then. Apart from the summer barbecues and the occasional international outing to the Efteling with "the Dutch colleagues", the engineers also get to know each other in a sporty way.

"We get together with our colleagues twice a year. Kurt, our branch manager, tries to organise a sporty activity. A go-karting competition, a rope course. We have also completed a swamp obstacle course in Oudenaarde. It is actually a course set out above a swamp. We were linked to each other with the inner tube of a bicycle tyre and we had to complete a course that primarily consisted of poles and planks set out above a swamp. And of course we all got soaked by the end of it."

The right attitude

ACE is looking for mechanical engineers who are eager to learn

According to Klaas, ACE looks very carefully at its employees' capabilities and ensures that they grow towards the correct position. According to him, the right attitude is part of the process:

"You have to be willing to learn, try to be an inventive problem solver or be able to tackle a project a certain way. It also helps to have an inter-disciplinary mindset, to show an interest in things that are not directly related to your area of expertise. Sometimes you need to be willing to take a step back and look at the whole picture."

Klaas continues: "I am very satisfied about the type of work that I can do at ACE. Here you are given the opportunity to carry on developing your talents. I am also involved in deciding what I am going to do or what we as ACE will take on as projects, if there is a choice in the matter. This freedom is definitely an added bonus of working for ACE. Do you also want to start working as a mechanical engineer at ACE? Call or e-mail me if you have any questions after reading my career story, Klaas adds."

LOOKING FOR A NEW CHALLENGE?

Check out our vacancies now and apply online today! Our team will be happy to help you discover your possibilities at ACE development & engineering.